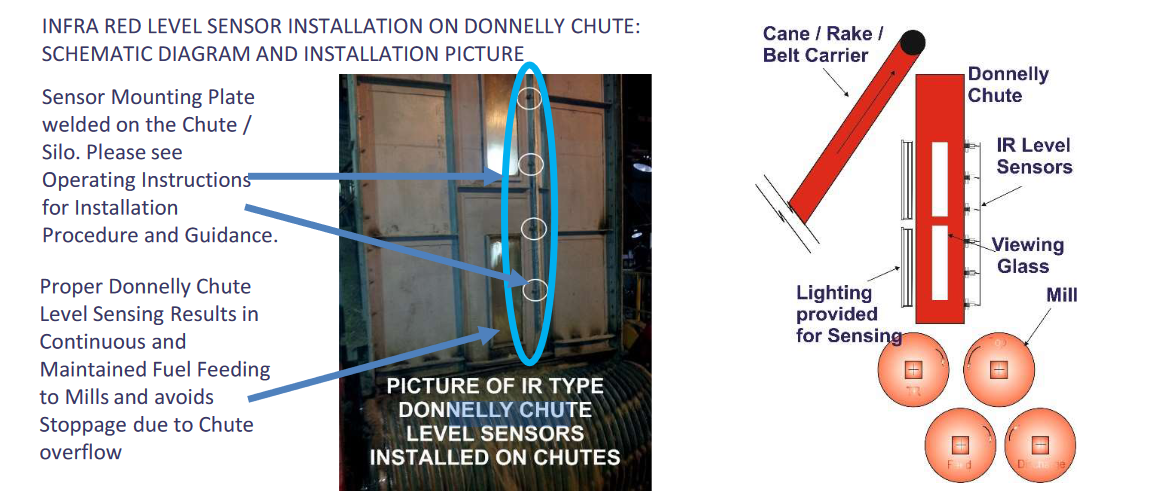

DONNELLY CHUTE LEVEL SENSING AND TRANSMISSION SYSTEM

INFRA RED DONNELLY CHUTE LEVEL SENSORS

YUTECH INFRA RED LEVEL SENSORS:

- Yutech invented this Technique in 1986.

- 100% True Donnelly Chute Level Detection

- No False Indications Due To Bagasse Powder

- No False Indications Due To Cane Pieces

- No False Indications Due To Juice Mist, Water Mist, Sticky Juice Residues, Juice Films And Dirt, Bagasse Powder & Juice Mix Formed On The Donnelly Chute Walls

- True Chute Level Detection Leads To Excellent Control

- Water Ingress And Dirt Proof

- Yutech IR Sensors Have Built-In Raining Bagasse Compensation And Easily Sense Level Through Raining Bagasse And Juice Moisture

- Infra-Red Light Is Known For Deep Penetration. It Is Used In Military Applications For Night Vision And Medical Applications Like Deep Fomentation Hence The Choice Of IR For This Critical Application.

- 500+ Sugar Mills Use Yutech IR Sensors In India, Asia Pacific, African Regions , USA.

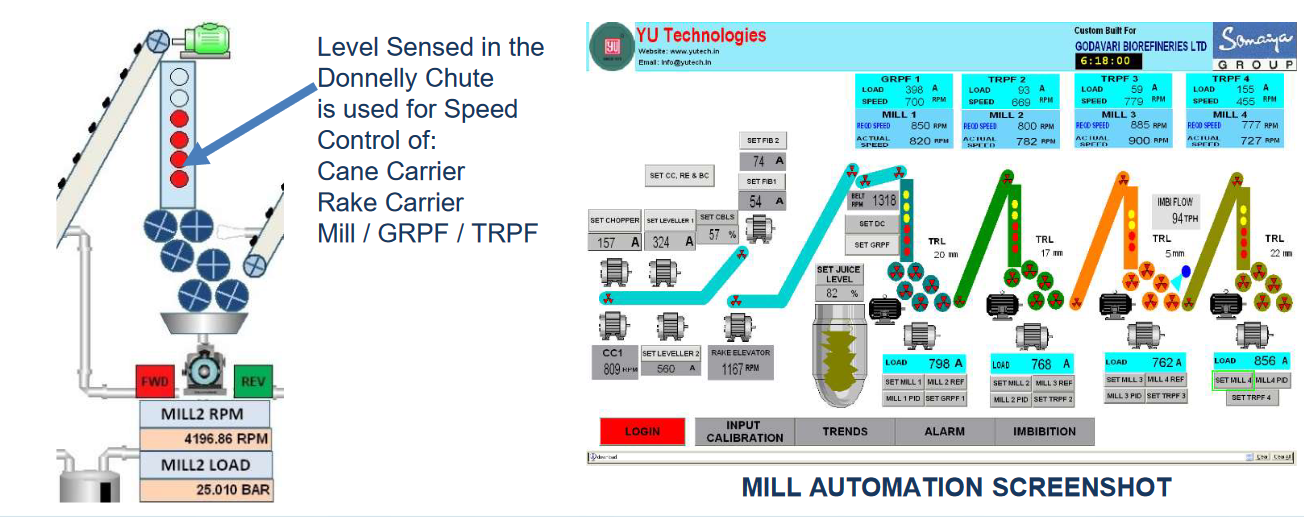

MILL AUTOMATION LIVE SCREENSHOT SHOWING CHUTE LEVEL INDICATION AND LIVE SCREENSHOT :

BUILT-IN RAINING BAGASSE COMPENSATION: To Accurately Sense, Analyze, Calculate Andderive Accurate Chute Level Within A Very Challenging Environment Of Residual Juicedirt, Sticky Bagasse Dust And Vibration

TECHNICAL SPECIFICATIONS FOR DONNELLY CHUTE LEVEL SENSING AND TRANSMISSION SYSTEM :

- Power Supply: 85 - 265 VAC, 50 - 60HZ

- Analyzer Enclosure: IP67 Field Mounted Dust And Moisture-Proof

- Input: IR Sensor Signals

-

Calibration can be done from :

- Keyboard: Keyboard with 5 Keys is provided in the Analyzer.

- Display: 4 Digit Led Dual Display, Led As Per Number Of Levels

-

Signal Output:

- 4 - 20 mA Processed Measured or Analyzed Variable Output

- Potential-Free Relay Output for each Sensor Input

PRODUCT CODES FOR DONNELLY CHUTE LEVEL SENSING AND TRANSMISSION SYSTEM OF VARIOUS SENSOR COMBINATIONS ARE GIVEN BELOW:

- A15DCAACIR4C1R4FM (4 Level System)

- A15DCAACIR6C1R6FM (6 Level System)

- A15DCAACIR8C1R8FM (8 Level System)

- A15DCAACIR10C1R10FM (10 Level System)

- A15DCAACIR12C1R12FM (12 Level System)

- A15DCAACIR16C1R16FM (16 Level System)

PRODUCT CODES FOR INFRA-RED DONNELLY CHUTE / BAGASSE SILO LEVEL SENSOR:

ASDDCLIRS10: Use For Chute Level Sensing Before Maceration Water Is Applied.

ASDDCLIRS12: Use For Chute Level Sensing After Hot Water Maceration Is Applied. It Is The Hightemperature Variant Which Can Withstand Operating Temperatures Up To 90°c.