APPLICATION OF CSD OR IRIS VALVE FOR WWTP, STP, AND ETP AERATION CONTROL

WASTEWATER TREATMENT AERATION CONTROLS WITH CSD OR IRIS VALVE

AERATION CONTROL FOR WASTEWATER TREATMENT PLANT:

Aeration is a Crucial Process in any Wastewater, be it Municipal Sewage or Industrial Effluent Treatment. In Aerobic Conditions, like in a Municipal Sewage Treatment Plant, the incoming Sewage includes Nitrogen, and in Anaerobic Conditions Effluent includes Dissolved Metals like in form of Ferrous Compounds, Chemicals like Hydrogen Sulphide and other Volatile Organic Compounds, in such Effluent, Oxidization helps to convert these chemicals to insoluble precipitates which can be removed or filtered out.

This Nitrogen is in the form of Ammonia, and it is usually present in the water in the form of ammonium ions. This ammonia is converted into its Nitrite by certain Bacteria, which are the Ammonia-Oxidizing Bacteria. Furthermore, the Nitrite is converted into Nitrate by another set of Bacteria, which are the Nitrite-Oxidizing Bacteria. This process, which converts Ammonia to Nitrite and further converts Nitrite to Nitrate, is called Nitrification and requires Oxygen.

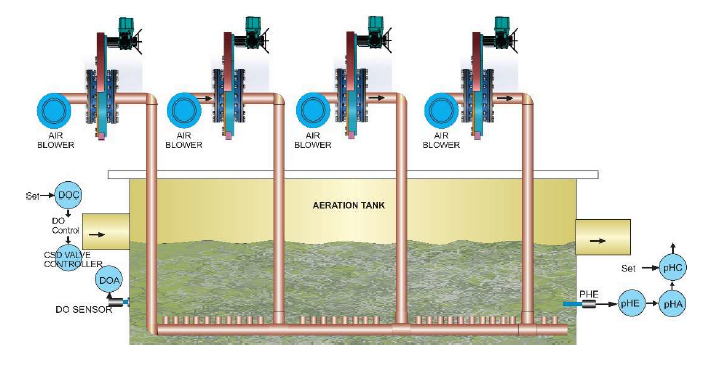

The Oxygen in the Effluent is in the form of Dissolved Oxygen (DO). And as the Concentration of DO affects the Nitrification Rate, DO needs to be controlled. Similarly, in Anaerobic Conditions also the Oxygen needs to be controlled. Various Aeration Control Methods are employed where the Iris Valve is Constant so that the Air Pressure isn't compromised while the Air Flow is regulated. Please go through the CSD or Iris Valve Brochure or scroll down to see the advantages and Flow Profile of CSD or Iris Valve.

Methods to Control DO in Sewage or Effluent Water:

- Monitoring the Dissolved Oxygen using DO Sensors, Ammonia Content using Ion Selective Electrodes, Turbidity Sensors, and Controlling Air Intake.

- CSD or Iris Valve is regulated as per the requirement from the Central or Local Controllers.

Aeration Control in Aeration Tank:

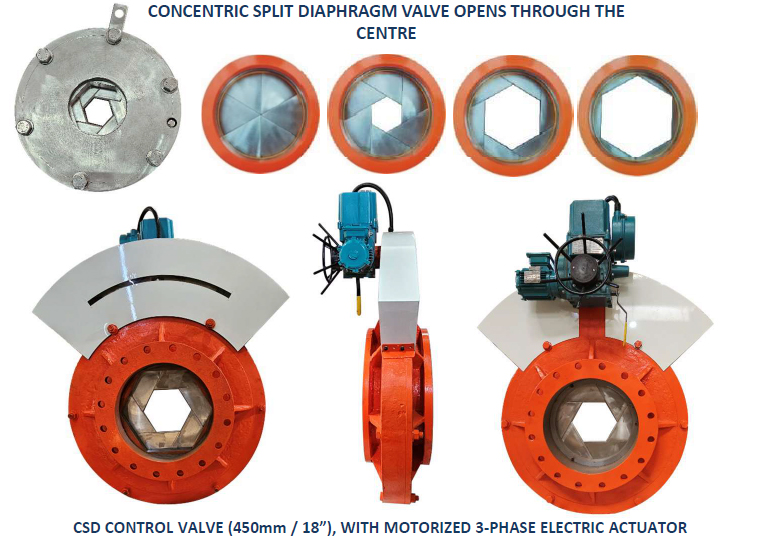

CONCENTRIC SPLIT DIAPHRAGM (CSD) VALVE ALSO CALLED IRIS VALVE

ELECTRIC OR PNEUMATIC ACTUATION WITH POSITIONER

Flow Control Applications:

- Sugar Industry: Sugar Syrups, Molasses, Massecuites, Lime (Caoh) Slurry, Etc.

- Pharma And Chemical: Slurries, Multiple Kinds Of Viscous Fluids, And Free-Flowing Materials Or Powders Or Granules

- Wastewater Treatment Plants: Wastewater From Municipalities And Industries, Air Flow Regulation For Aeration Control Application

- Pulp And Paper Industry: Paper Pulp And Fluids With Fibrous Suspensions

- Free-Flowing Granules Or Pellets: Salt, Powders, Grain, Polymer Granules With A Particle Size Between 0.5Mm And 10Mm

- Air And Gas: Industrial Hot And Cold Air, Non-Corrosive Gases

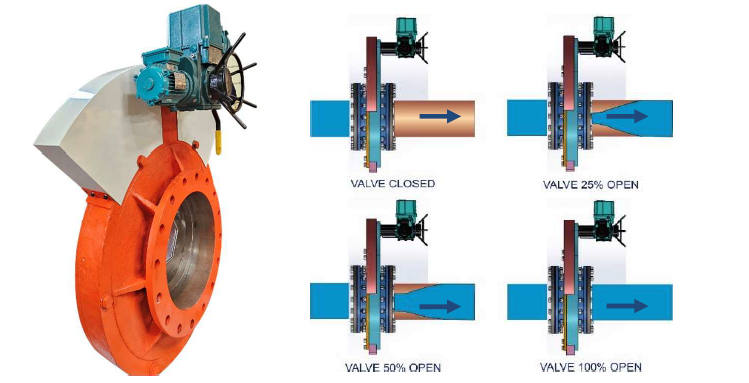

Flow Profile Of Concentric Split Diaphragm Valve:

Gravity Discharge Installation:

Inline Installation: The Flow Profile Through The Split Diaphragm’S Center, Minimizes Pressure Drop, Noise, And Flow Turbulence Throughout The Entire Flow Regulation Range

Other Applications:

- Controlled Gravity Flow Of Grains Or Pellets Or Powders With A Particle Size Between 0.5 Mm And 10 Mm

- Ideal For Controlling Gravity Flow Control Of Flow Of Slurries / Semi-Solids / Concrete And Other Fluids

- Ideal For Ratio Control Of Two Or More Ingredients Falling In A Vessel

- Hot And Cold Airflow Control

Characteristics And Advantages Of IRIS OR CSD Valve:

- Rugged build quality for long life and frequent throtteling and on / off Operations.

- Heavy-duty rugged valve construction absorbs all shocks and vibrations.

- Valve internals designed to operate under heavy media loads.

- Precise flow control without hysteresis due to the concentric opening of the Split diaphragm.

- Energy saving whilst flow control due to free passage through concentric Opening.

- Low noise and no flow turbulence throughout the full flow control range.

- Very Low Maintenance.

- High Flow Capacity

- Lower Pressure Loss Than Other Valve Types Due To Free Passage Through Concentric Opening.

Valve controller with the following features:

- Pid control action for flow control

- Remote set variable facility for flow control as per another process Parameter

- Built-in auto-manual station

- Dcs input facility (4-20ma dcs control output for valve control given Through toggel switch. This avoids need of additional junction box on field)

- Toggle switch for switching between dcs output and local controller Output

- Optional valve position feedback as 4-20ma

Pneumatic Actuation:

- Pneumatic Clylinder With Electro-Pneumatic Positioner For Smooth Linear

- Control Action

- Operating Air Pressure: 2 - 7 Kg/Cm2

- Input: 4-20Ma From Any External Source

Electric Motorized Actuation:

- Electric Actuator Geared Ac Induction Motor

- Operating Voltage: Single Phase 110 Vac 60Hz / 230 Vac 50 Hz Or Three Phase 440 Vac 50 / 60Hz

- Input: 4-20Ma From Any External Source Or Push Buttons

Hand Wheel:

- Geared Hand-Wheel

Hand Lever:

- Hand Level Operated

IRIS or CSD Valve Specifications:

| Valve Type | : | IRIS Or Concentric Spilt Diaphragm Valve |

| Sizes | : | 2" (50mm), 3" (75mm), 4" (100mm), 6" ( 150mm), 8" (200mm), 10" (250mm), 12" (300mm), 16" (400mm), 18" (450mm) |

| Body Material | : | Standard: Ms Fabricated On Request: SS 316L / SS 304 / LCB |

| Petal Segments | : | Standard: Ss 304. On Request: Ss 316L, Duplex Steel 2205 / Other Special Material |

| Bearings And Wedges Material | : | Standard: Ss 304. On Request: Ss 316L, Duplex Steel 2205 / Other Special Material |

| Sheathing | : | PTFE / PU |

| Actuation | : | Pneumatic Linear / Electric - Motorized / Hand - Wheel |

| Actuator Stroke / Torque | : | As Per Valve Size And Line Pressure |

| Positioner | : | Electro-Pneumatic / Electronic |

| Position Feedback : (Optional) | : | 4 - 20 MA / 0 - 5 VDC |

| Input (For Actuated Valves Only) | : | 4 20 Ma From Any External Source Or Push Buttons For Open And Close |

| Media Temperature And Pressure | : | -45 To 160°C, 0-10Kg/cm2 |