CONTINUOUS VACUUM PAN (CVP) AUTOMATION

WITH BRIX ANALYZER AND DENSITY BRIX SENSOR

Continuous Pan Automation Features:

- Accurate Compartment Brix Sensing Using Fluid Density Brix Sensor A24Fdsrs2 Or HF Brix Sensor

- Controlled Intake As Per Set Point To Accurately Maintain Compartment Brix

- No False Grains, Hence Less Water And Steam Consumption Thus Increased Bagasse Saving

- Increased Sugar Production

- Temperature Sensing Throughout The Cv Pan Ensures Uniform Temperature Inside The Cv Pan Body

- Standalone System For Cv Pan Having Communication With Main Plc / Dcs System

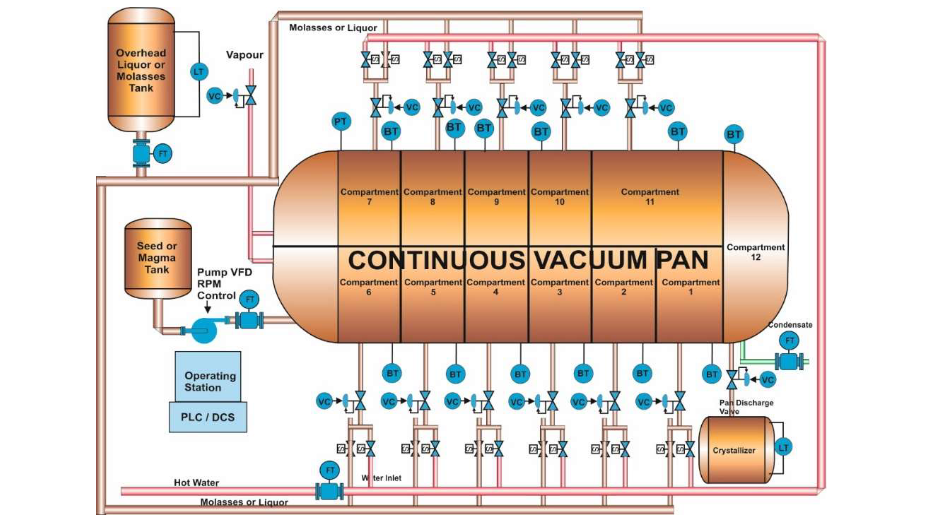

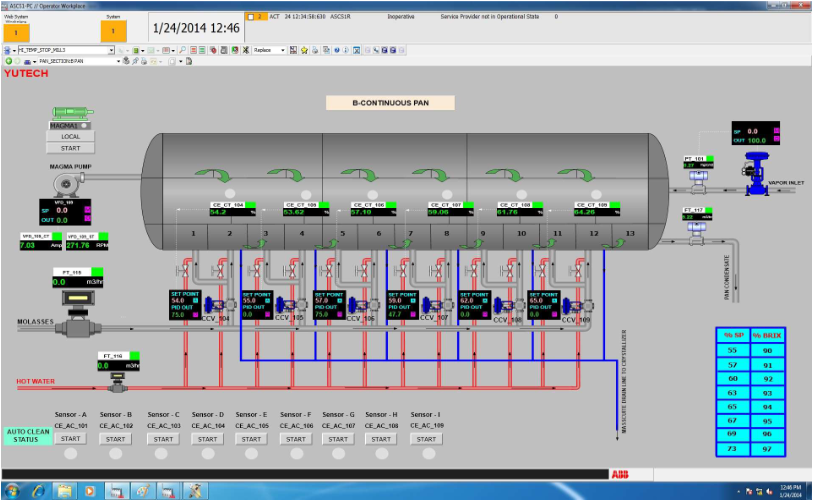

CONTINUOUS VACUUM PAN AUTOMATION

Seed or Magma Flow Control with respect to Molasses or

Liquor Flow:

- Molasses and Seed Flowmeters sense Flow.

- Ratio Controller delivers exact Flow of Seed wrt Molasses Quantity by Controlling Seed / Magma Pump VFD.

Individual Compartment Brix Control by Auto Feeding Molasses or Water into each Compartment:

- Fluid-Density-Brix Or Brix Sensing Of Each Compartment By Yutech Fluid-Density-Brix Analyzer Or Yutech Brix Analyzer

- Control Of Molasses Intake Valve With Brix Set Point, And Fluid-Density-Brix As Process Value In A Pid Mode

- Addition Of Water Only If Extremely Necessary.

Fluid Density Brix Analyzer Technical Specifications:

Product Code: A15FDACFM1230 / A24FDACFMEM1230

- Power Supply: 85 - 265 VAC, 50 - 60HZ

-

Inputs:

- Fluid-Density Sensor

- RTD PT100 Temperature Sensor

- 8-Point Level Sensors (Conductivity-Based Digital Switch Type)

- 4-20Ma: Input From Vacuum Transmitter (Optional, Not A Part Of Standard Supply)

- 4-20Ma: Input From Differential Pressure Transmitter With Extended Diaphragm With Capillary Tubes (Optional, Not A Part Of Standard Supply)

- Outputs:

- 4-20MA: Brix Output

- 4-20MA: PID Output For Brix Control (Brix As Pv For Pid Control)

- 2 Potential-Free Relay Outputs

- Display:

- For Product Code - A15FDACFM1230: 7-SEGMENT LED Display

- For Product Code - A24FDACFMEM1230: 7-SEGMENT LED Display And Lcd Display

- Enclosure: Field Mounted Ms Powder Coated, Ingress Protection Class Ip67

- Communication: ETHERNET: Modbus Tcpip (Product Code: A24FDACFMEM1230)

Fluid Density Sensor Technical Specifications:

Product Code: A24FDSRS1, A24FDSRS2, A24FDSRS3

- Type: Motorized Fluid Density Sensor

- Power Supply: 24VDC From The Analyzer (Not To Be Connected To Any External Source).

-

Built-In Thermowell With RTD PT100

Material Of Construction : SS304 / SS316L - PTFE Sheathed Conductivity Probe 8 Nos.: SS304 / SS316L With PTFE Sheath

-

Material Of Construction:

Wetted Rotary Parts: SS304 / SS316L

Wetted Stationary Parts: MS Chrome Plated / SS304 / SS316L - For Food-Grade, SS-304 Full Sensor Body: Add Fgss To The Pc. Ex: A24FDSRS3FGSS

- For Acidic Chemicals, SS-316L Full Sensor Body: Add SSL To The Pc. Ex: A24FDSRS3SSL

Fluid Density Sensor Model Guidance For Various Applications:

A24FDSRS1: Batch Pan, Horizontal Continuous Pan, Vertical Continuous Pan

A24FDSRS1: Batch Pan, Horizontal Continuous Pan, Vertical Continuous Pan

For More Details On The Fluid-Density-Brix Analyzer And Control System With Fluid-Density Sensor Download The Brochure From Our Website.