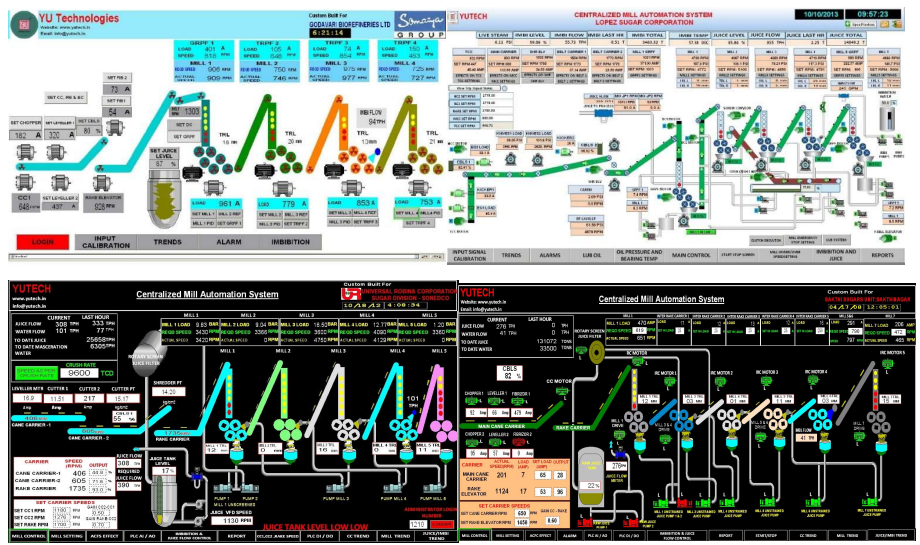

SUGAR MILL AUTOMATION SYSTEM

AUTO CANE FEEDING, MILL SPEED, MACERATION, JUICE FLOW CONTROLS & INTERLOCKS

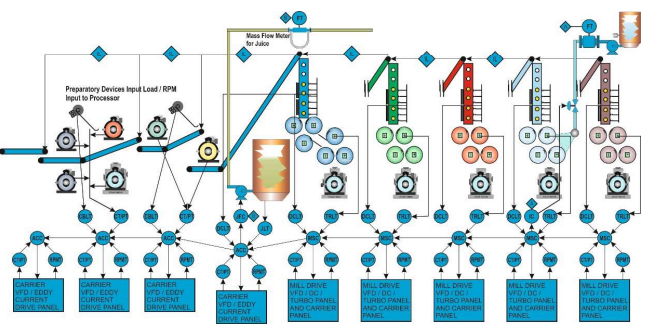

Sugar Mill Automation Schematic Diagram

Sugar Mill Automation Stabilizes Entire Factory Operationm

Operational Advantages:

Increased Crushing or Milling with the Same Equipment:

- Continuous, Un-interrupted and Constant Rate of Feeding maintains Donnelly Chute Levels and increases Mill Performance as well as Throughput

- Elimination of Choking at Preparatory Devices, Mills, Chutes, or Carriers reduces downtime

- Maintained Juice to Maceration Water Ratio increases Evaporation Efficiency

- Optimum Mill Speeds with respect to Loads and Levels ensure good Milling Results at all times

- Effective water saving and cutting off water flow when crushing is stopped.

- Constant Juice Flow for the Process ensures even loading in the Boiling House and Stabilizes and Reduces the Steam Consumption which means higher Boiling House efficiency and Bagasse Saving

- Stable Juice Flow also helps in better Juice pH Control which in turn ensures better Juice and Sugar Colour which means better Sugar Price

- Constant Dry Bagasse Feed to Boilers ensures better Steam Generation Efficiency

- All the above is only possible when Donnelly Chute Levels are accurately sensed in a well tuned and synchronous Mill Automation System.

Improve Milling Performance by YUTECH MILL AUTOMATION SYSTEM AND INFRA-RED DONNELLY CHUTE LEVEL SENSING SYSTEM:

- Constant Load on Preparatory Devices ensures Better Cane Preparation resulting in a better Preparatory Index

-

Constant Load on Mills and Level in all Donnelly Chutes results in Power and Steam Savings as well as improves Mill Performance in terms of:

- Increased Extraction

- Better Reduced Mill Extraction or RME

- Reduced Bagasse Pol and Moisture

- Constant Power Demand in Mill House which comprises about 40% or more of the overall Factory Power Consumption results in Overall Stable Power throughout the Factory

-

Constant Load on Mills also results in Lesser Mechanical Wear & Tear

- Lesser Maintenance Cost

Automatic Mill Automation System Features:

SENSING:

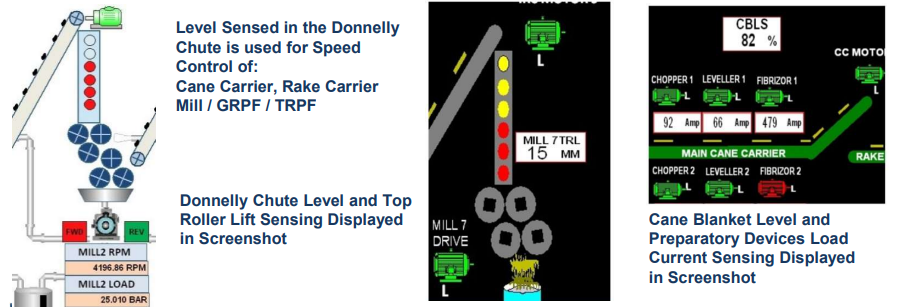

- Infra Red Type Donnelly Chute Level Sensing of all Donnelly Chutes

- Hall's Effect Type Cane Blanket Level Sensing

- Hall's Effect Type Top Roller Lift Sensing

- All Preparatory Devices and Mill (Pressure Feeders if driven by separate Drives) Drive Load Current Sensing by High Precision Non-Invasive CT Protectors and Isolating Converters to sense

- Preparatory Devices and Mill Turbine Chest Pressure Sensing, by Pressure Transmitters

- Live Steam Pressure Sensing, by Pressure Transmitters

- Hydraulic Drives Pressure Sensing, by Pressure Transmitters

- Maceration Water Flow Sensing

- Juice Tank Level Sensing

- Juice Flow Sensing by Mass or Magnetic Flowmeter

- Mill Hydraulic Pressure Sensing, by Pressure Transmitters

- Mill and Preparatory Devices Bearing Temperature Sensing and Monitoring

- Motor Winding / Motor Cage Temperature Sensing and Monitoring

- All Inter-Carriers, Cane Carriers, Bagasse Carriers, Mills, Pumps, On / Off / Run Condition Sensing and Inter-Lock Protection

PROCESS CONTROLS:

- Automatic Cane Feed Control: Speed Control of all Cane Carrier, Rake Carriers, Belt Carriers etc., which Feed Cane to the Mills

- Automatic Mill Speed Control: All Mill Speed Controls and Variation with respect to individual Mill’s Load and its Donnelly Chute Level

- Maintain Mill and Pressure Feeder Speed Ratio if driven by separate Drives

- Next Mill Donnelly Chute Level and Speed Feedback for Mill Speed Control

- Maintained Mill Speed Safe Operating Band

- Auto Maceration or Imbibition Control: Controlled Maceration Water Flow as per Dynamic Process Conditions

- Juice Flow Stabilization: Controlled and Constant Juice Flow to Process / Boiling House as per Dynamic Process Conditions

Alarms, Over-Riding and Safety Controls:

All following conditions will Raise Alarm and Implement Safety Controls as per Factory Conditions and Customization to User Needs:

- Donnelly Chute Levels for Cane Carrier Speeds

- Tripping of any Carrier / Pump / Mill will Trip all preceding Carriers

- Tripping of any Mill will Trip all preceding Mills (By User’s Choice)

- Cane Juice Tank Level increase beyond Preset High Level to Reduce Cane Carrier Speeds

- Cane Juice Tank Level increase below Preset Low Level to increase Cane Carrier Speeds (After Checking other Process Dynamics) and Juice Pump Speed Reduction (By User’s Choice)

YUTECH SUGAR MILL AUTOMATION SYSTEM SCREENSHOTS