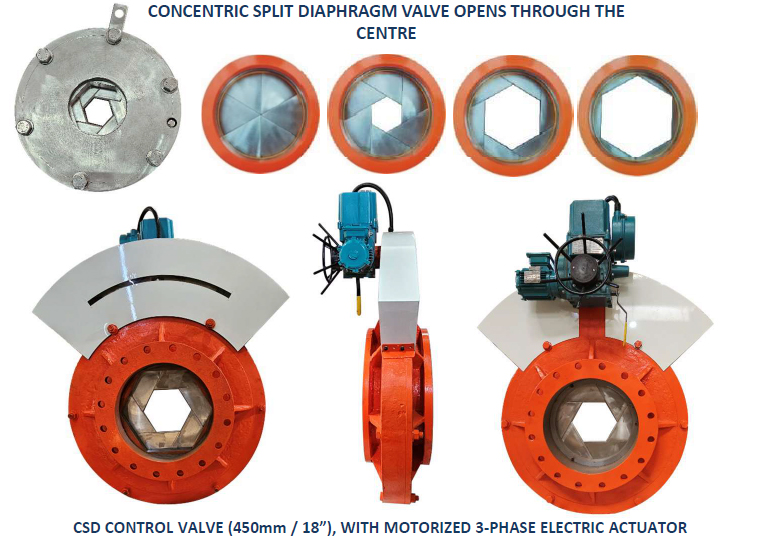

CONCENTRIC SPLIT DIAPHRAGM (CSD) VALVE ALSO CALLED IRIS VALVE

ELECTRIC OR PNEUMATIC ACTUATION WITH POSITIONER

Flow Control Applications:

- Sugar Industry: Sugar Syrups, Molasses, Massecuites, Lime (Caoh) Slurry, Etc.

- Pharma And Chemical: Slurries, Multiple Kinds Of Viscous Fluids, And Free-Flowing Materials Or Powders Or Granules

- Wastewater Treatment Plants: Wastewater From Municipalities And Industries, Air Flow Regulation For Aeration Control Application

- Pulp And Paper Industry: Paper Pulp And Fluids With Fibrous Suspensions

- Free-Flowing Granules Or Pellets: Salt, Powders, Grain, Polymer Granules With A Particle Size Between 0.5Mm And 10Mm

- Air And Gas: Industrial Hot And Cold Air, Non-Corrosive Gases

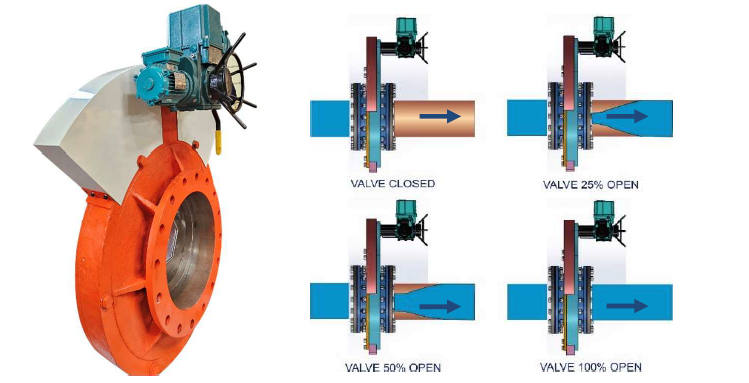

Flow Profile Of Concentric Split Diaphragm Valve:

Gravity Discharge Installation:

Inline Installation: The Flow Profile Through The Split Diaphragm’S Center, Minimizes Pressure Drop, Noise, And Flow Turbulence Throughout The Entire Flow Regulation Range

Other Applications:

- Controlled Gravity Flow Of Grains Or Pellets Or Powders With A Particle Size Between 0.5 Mm And 10 Mm

- Ideal For Controlling Gravity Flow Control Of Flow Of Slurries / Semi-Solids / Concrete And Other Fluids

- Ideal For Ratio Control Of Two Or More Ingredients Falling In A Vessel

- Hot And Cold Airflow Control

Characteristics And Advantages Of IRIS OR CSD Valve:

- Rugged build quality for long life and frequent throtteling and on / off Operations.

- Heavy-duty rugged valve construction absorbs all shocks and vibrations.

- Valve internals designed to operate under heavy media loads.

- Precise flow control without hysteresis due to the concentric opening of the Split diaphragm.

- Energy saving whilst flow control due to free passage through concentric Opening.

- Low noise and no flow turbulence throughout the full flow control range.

- Very Low Maintenance.

- High Flow Capacity

- Lower Pressure Loss Than Other Valve Types Due To Free Passage Through Concentric Opening.

Valve controller with the following features:

- Pid control action for flow control

- Remote set variable facility for flow control as per another process Parameter

- Built-in auto-manual station

- Dcs input facility (4-20ma dcs control output for valve control given Through toggel switch. This avoids need of additional junction box on field)

- Toggle switch for switching between dcs output and local controller Output

- Optional valve position feedback as 4-20ma

Pneumatic Actuation:

- Pneumatic Clylinder With Electro-Pneumatic Positioner For Smooth Linear

- Control Action

- Operating Air Pressure: 2 - 7 Kg/Cm2

- Input: 4-20Ma From Any External Source

Electric Motorized Actuation:

- Electric Actuator Geared Ac Induction Motor

- Operating Voltage: Single Phase 110 Vac 60Hz / 230 Vac 50 Hz Or Three Phase 440 Vac 50 / 60Hz

- Input: 4-20Ma From Any External Source Or Push Buttons

Hand Wheel:

- Geared Hand-Wheel

Hand Lever:

- Hand Level Operated

IRIS or CSD Valve Specifications:

| Valve Type | : | IRIS Or Concentric Spilt Diaphragm Valve |

| Sizes | : | 2" (50mm), 3" (75mm), 4" (100mm), 6" ( 150mm), 8" (200mm), 10" (250mm), 12" (300mm), 16" (400mm), 18" (450mm) |

| Body Material | : | Standard: Ms Fabricated On Request: SS 316L / SS 304 / LCB |

| Petal Segments | : | Standard: Ss 304. On Request: Ss 316L, Duplex Steel 2205 / Other Special Material |

| Bearings And Wedges Material | : | Standard: Ss 304. On Request: Ss 316L, Duplex Steel 2205 / Other Special Material |

| Sheathing | : | PTFE / PU |

| Actuation | : | Pneumatic Linear / Electric - Motorized / Hand - Wheel |

| Actuator Stroke / Torque | : | As Per Valve Size And Line Pressure |

| Positioner | : | Electro-Pneumatic / Electronic |

| Position Feedback : (Optional) | : | 4 - 20 MA / 0 - 5 VDC |

| Input (For Actuated Valves Only) | : | 4 20 Ma From Any External Source Or Push Buttons For Open And Close |

| Media Temperature And Pressure | : | -45 To 160°C, 0-10Kg/cm2 |