BOILER AND COMPLETE POWER PLANT AUTOMATION

DCS / PLC BASED TURNKEY POWER PLANT AUTOMATION SYSTEM

Boiler Automation Advantages And Schematic Diagram:

Boiler Automation Advantages:

- Improved Efficiency by 3-5%.

- Improved Steam to Fuel Ratio due to constant FW Temperature and increase in Boiler Efficiency (Please see Fuel Ratio Equation)

-

Optimum Combustion Reduces Un-burnt Fuel Losses This is evident from:

- Decrease in Oxygen and Increase in Carbon Dioxide Percentage in Flue Gas and at the same time reduction in Excess Air Percentage.

- Reduction in Flue Gas Carbon Monoxide Percentage.

- Reduction in Excess Air means optimum usage of Fan Drives and thus Power Saving.

- Maintained Steam Drum Level with Pressure Compensation Ensures Optimum Steam Generation while compensating for Shrink and Swell in the Drum Level.

- Reduction in Clinker Formation due to good combustion condition.

- Reduction in Thermal Shocks, Improves Equipment Life Expectancy.

- Energy Savings in Electricity, Fuel, Water, Steam.

- Equipment Protection.

-

All Key Performance Indicators are Highlighted and Recorded, hence Performance Records and Trends maintained which are used for:

- Fault Finding and Identifying the Reasons.

- Predictive Maintenance.

- Reduced Downtime.

- Ensure Maximum Up Time.

ADVANTAGES: Power Plant Automations Ensure Higher Efficiency:

Proper Combustion reaction in the Furnace Improves Boiler Efficiency, this in turn improves Steam to Fuel Ratio and leads to Fuel Saving. This can be demonstrated by Equation below:

Where:

- H = Enthalpy of Superheated Steam

- h = Enthalpy of Feed Water

- Fuel GCV: Fuel's Gross Calorific Value

Our focus on maintaining higher temperature at De-Aerator further improves this equation.

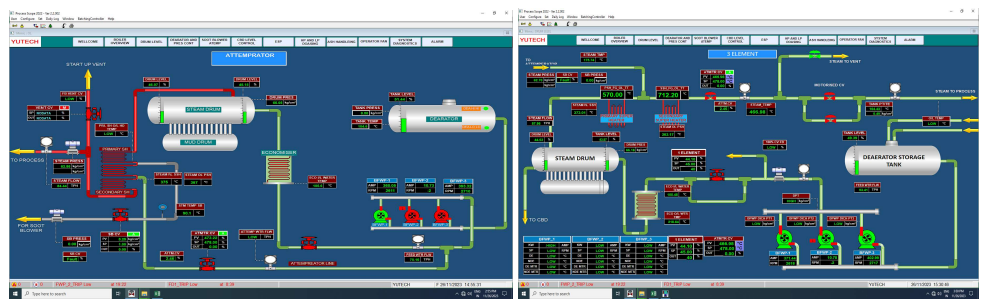

Steam And Water Controls:

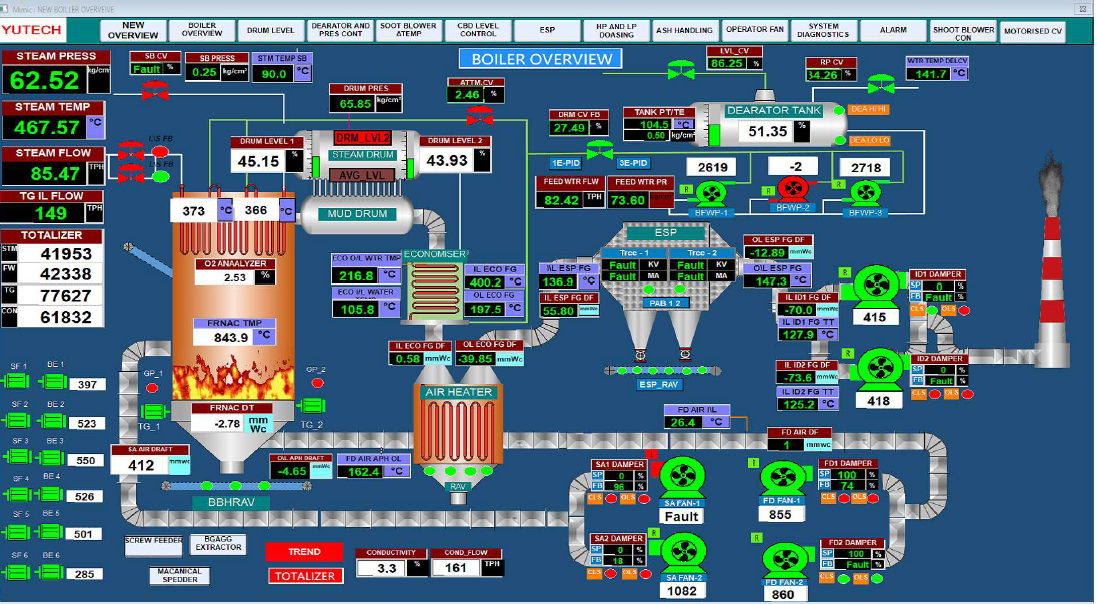

Screen Shot: Boiler Automation Overall

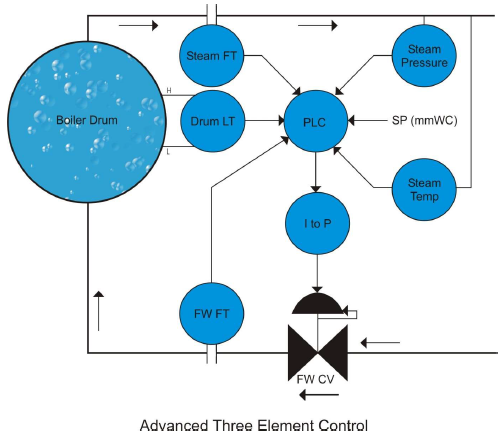

Advancedthree Element Control:

Drum Level, Steam Flow And Feed Water Flow Sensing

Feed Water Flow Control To Maintain Drum Level, Constant Steam Flow, Steam Pressure And Steam Temperature

Steam Pressure And Steam Temperature Compensation

Compensation Equation For Shrink And Swell In The Drum Level.

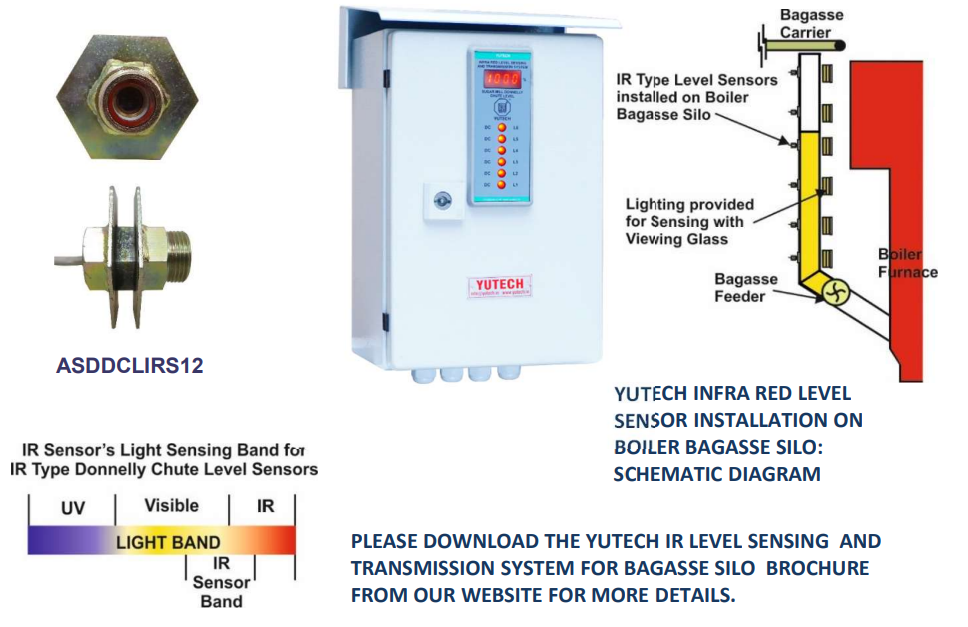

Yutech Infra Red Level Sensing And Transmission System For Boiler Bagasse Silo:

Microsys 3200 Et System Key Features

Unmatched Memory - 512Mb Expandable To 4Gb

- Best Clock Time - 720Mhz And Best Scan Time: 100Msec

- Bumpless, Balance-Less, And Glitch-Free Redundancy

- Unlimited Tags

- Inexpensive Upgrades

- Built-In Cloud Connectivity

-

Built-In Industrial Internet Of Things (Iiot) Connectivity

- Built-In Apis For Integration With Cloud Platforms, Mobile Apps To Make Data Accessible On Custom-Built Mobile Platforms And Web-Dashboards.

- Built-In Erp Connectivity

- A Highly Flexible And Scalable System Allows Configurations Lower Than 100 I/Os To Over 16,000 I/Os Which Can Be Extended Even To 24000 I/Os Per Subnet Mask. Meaning A New Network Expands Your I/Os By 16000 - 24000. Thus, There Is No Top Limit On I/Os

- Server-Less Basic Configuration With Multi-Master, Multi-Slave Topology

- Mean Time Between Failures (Mtbf): 12,07,420 Hrs.

- Mean Time To Repair (Mttr): Less Than 30 Minutes (>1/2 Hr), To Replace Hot-Swappable Module.

- System Availability: 0.999999, That'S Better Than 99.9999%

-

Automatic, Bump-Less, Balance-Less, And Glitch-Free Redundancies At All Levels As Below:

- Controllers

- I/O Modules

- Communication Buses Between Controllers And I/O Modules

- Communication Buses Between Controllers, And Engineering / Operator Stations

- Power Supplies.

- Diagnostic Information About Every System Element Is Available On Engineering Andoperator Stations

- Hot-Swappable System Elements Are Hot-Removable / Hot-Insertable

- Facility For Sd Card

- Io Sub-System Redundant Communication Ports: 2

- Two 100Mbps Redundant Ethernet Ports For Engineering And Operator Stations? Two Rs 232 Serial Ports

- Usb 2.0 Port: 1 For Interfacing Third-Party Communication Devices

- I/Os Per Controller: 512 Or 32 Modules. This Feature Maintains Best-In-Class Scan Time? Built-In Drivers For Modbus-Ip And Modbus-Rtu And For Audio Port (1 No.)

- Powerful Diagnostics

- 24 Vdc Power Supply

Microsys 3200 Et System: Software Tools

- Sysdev - Functional Block Diagrams (Fbd) Application Logic Development Tool

- Pscope 22 - Graphics User Interface

- Batch Management Tools

MICROSYS 3200 ET SYSTEM: MODULES

General Specifications:

- Channel-to-channel Isolation For Analog Modules

- Group Isolation Digital Modules

- All Modules Come With Status Indication LEDs For Individual Channels

- All I/O Modules And Bus Interface Modules Are Din-rail Mounted And Stacked Together

- Controllers Are Din-rail Mounted

- All I/Os And Interface Modules Are Hot-swappable

- Redundant Communication Interface Between I/O Modules And Controllers

- 24 Vdc Power To I/O Modules

- Prefab Cables

Bus Connector: T-bus Back-plane To Install Hot-swappable Modules

Analog Input Modules: ET-AI-2-8, ET-AI-2-16, ET-AI-2-24, 16-bit Resolution Analog Input Module

Digital Input Modules: ET-DI-2-8, ET-DI-2-16, 8-channel And 16-channel Digital Input Module

Analog Output Modules: ET-A0-2-8, ET-A0-2-16, 8 And 16-channel 16-bit Resolution Analog Output Module

Digital Output Modules: ET-DO-2-16, ET-DO-2-32, 16 & 32-channel Digital Output Module

Pulse Input Modules: ET-PI-2-8, 8-channel Pulse Input Module, Fr-range Up To 10 Khz

Ser Input Modules: ET-SE-2-15 15-channel Ser Module (SER Is Sequential Event Register Also Called SOE / SOER Meaning Sequence Of Events Register), Event Resolution: 1 Milli-Second

Bus Interface Modules: ET-BIM-1, ET-BIM-2